The IKO Construction Materials Testing Facility consists of three adjoining laboratories and their supporting services located in the Agricultural and Civil Engineering Building within the Fort Garry Campus. The details of the IKO Facility are as follows:

- Concrete Durability Laboratory

The objective of this laboratory is to simulate environmental effects on concrete and other building materials, and to assess their degradation due to chemical and/or physical attack. The laboratory houses the following instruments:

- 1-Freeze/thaw cabinet

- 2-Programmable environmental chamber

- 3-UV tester

- 4-Polisher/grinder for sample preparation

- 5-Resonance frequency apparatus

6-Rapid chloride permeability test (RCPT)

- Microstructure and Structural Health Monitoring Laboratory

- Materials Laboratory

- Supporting Equipment

RCPT Resonance Frequency

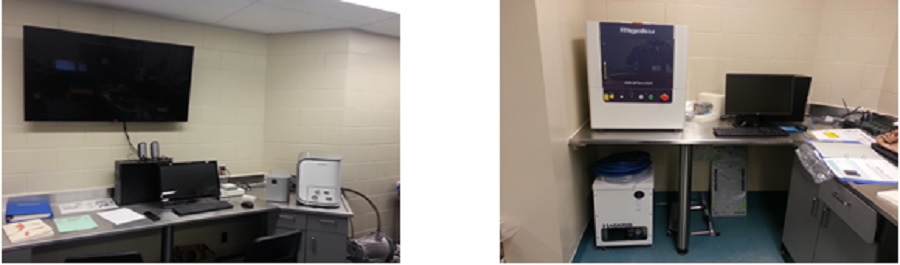

This laboratory houses advanced analytical equipment for characterization of building materials at the microstructural scale. It includes the following instruments:

1-Optical microscope (X40)

2-Scanning electron microscope (SEM: X60,000) with an integrated elemental dispersive X-ray system

3-X-ray diffraction analyzer (XRD)

4-Differential scanning/thermogravimetric calorimeter (DSC/TGA)

5-Isothermal calorimeter (IC)

6-Mercury intrusion porosimeter (MIP)

7-Structural health monitoring tools and instruments

SEM XRD

IC DSC

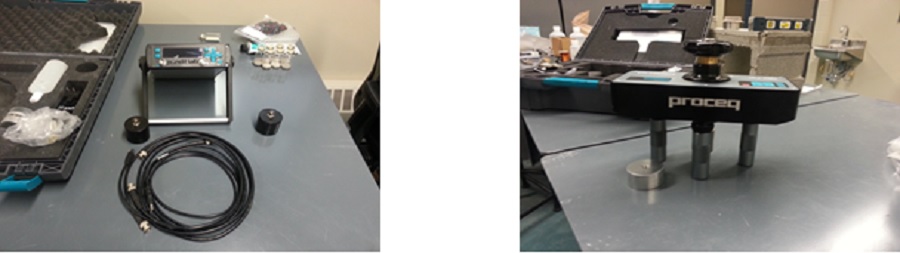

The laboratory contains space for fabrication and testing of small scale structural elements and materials. The laboratory contains the following devices:

1-A servo-electric Instron Universal Testing Machine (capacity 300 kN)

2-Portable popsicle stick bridge load frame

3-A digital length comparator

4-Setting time equipment (penetration resistance)

5-A sieve and shaker apparatus

6-Air content meter for fresh concrete

7-Setting time penetrometer

8-Ultrasonic pulse velocity apparatus (UPV)

9-Pull-off tester

10-Data acquisition systems

11-Instrumentation supplies (e.g. displacement transducers, pi gauges, strain gauges)

UPV Pull-off Tester

UPV Pull-off Tester

The IKO Construction Materials Testing Facility is supported by the existing concrete mixing laboratory, a large preparation area and McQuade Structures Laboratory (full-scale prototypes and structural members under both static and dynamic loading in an infinitely variable format., which include the following tools and instruments:

1-Concrete compression tester

2-Three concrete mixers

3-Aggregate drying oven

4-Concrete capping station

5-Concrete surface grinder

6-DAQ(s), data loggers, pH meters, etc.

7-Concrete saws and coring tools

8-Two walk-in environmental chambers, including one with built-in frames

9-18 m x 19 m strong floor and an L-shaped reaction wall (3.5 m wide × 6 m high per leg)

10-Two closed loop servo hydraulic testing machines (1000 and 5000 kN),

11-Four 1000-kN capacity MTS actuators (one fully-dynamic and 3 quasi-static)

12-A number of portable universal steel reaction frames

13-Two 60 gpm pumps and controllers for the servo-controlled apparatus